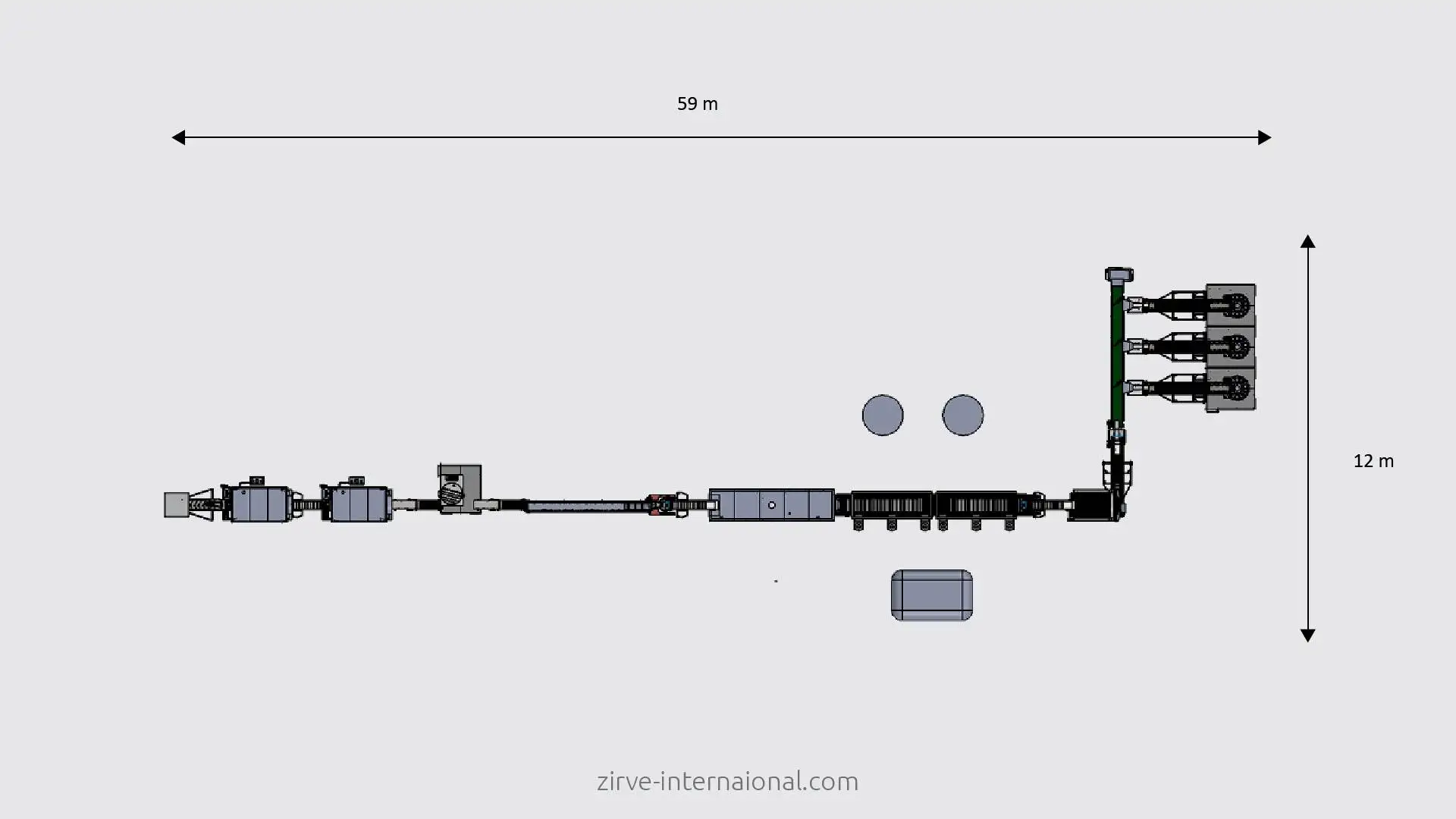

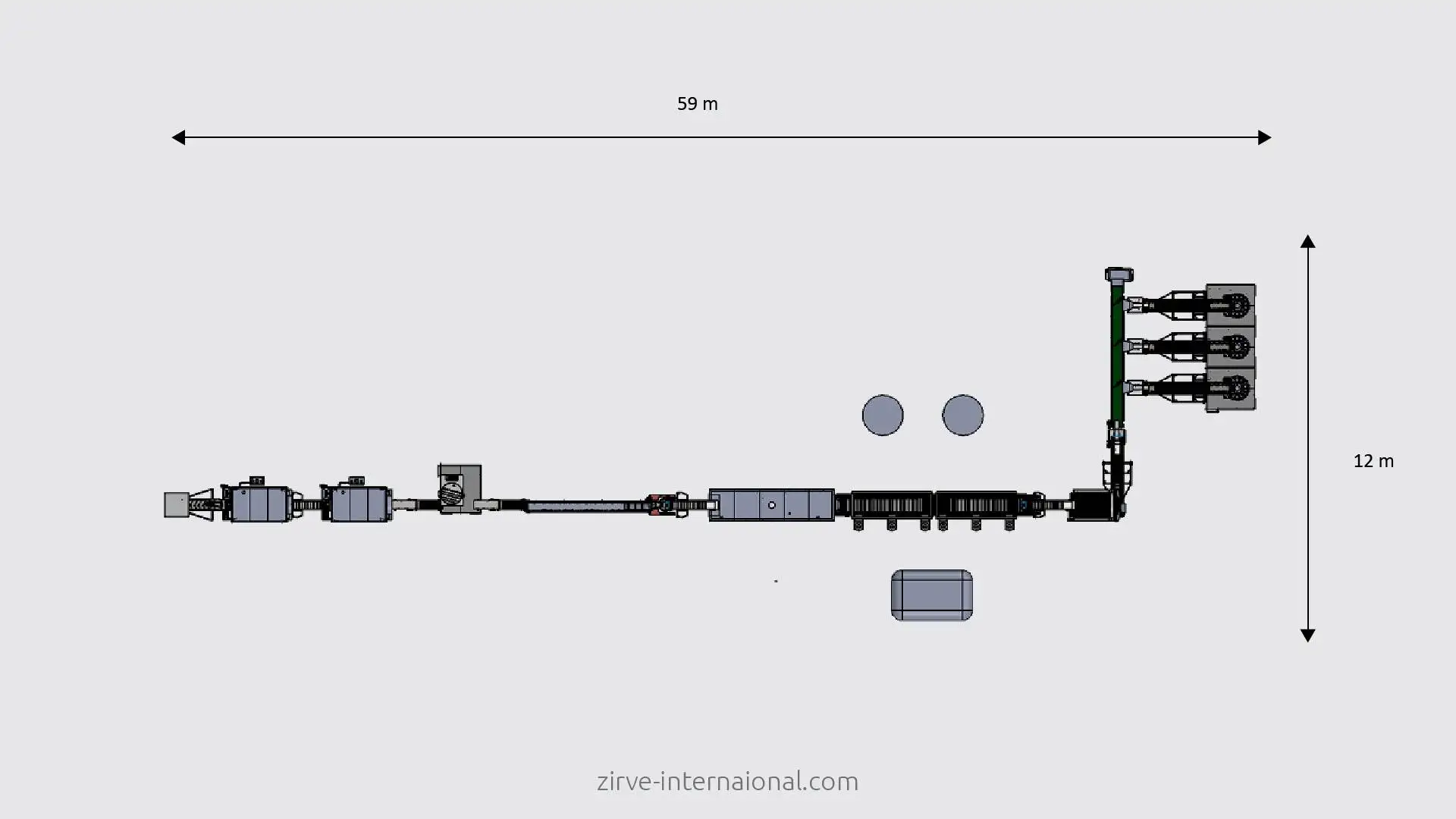

<h1>Mechanical Peeling Station — Fixed Tub & Rotating Floor with Water Loop and Filtration</h1><ul><li><p><strong>Operating Principle:</strong> Speed-controlled abrasive peeling based on friction of potatoes against a rough inner lining with adequate water flow and pressure, within a defined dwell time, to achieve full, uniform peel removal.</p></li><li><p><strong>Compatibility with Varieties:</strong> Suitable for different potato types/conditions (frozen, fresh, Cruz, Rosetta, Hormuz, etc.).</p></li><li><p><strong>Service Life:</strong> Food-grade, high-resistance abrasive lining with an operating life of up to <strong>5 years</strong> (higher reliability versus alternative methods).</p></li></ul><h2>Construction & Mechanism</h2><ul><li><p><strong>Tub:</strong> Fixed cylindrical vessel with a durable, rough inner layer.</p></li><li><p><strong>Floor:</strong> Rotating base covered with a matching abrasive layer to boost peeling efficiency.</p></li><li><p><strong>Peeling Action:</strong> Top infeed with metered quantities/weights and medium-pressure water; centrifugal force plus continuous friction (potato-to-potato and potato-to-wall) removes skin from all sides.</p></li><li><p><strong>Peel Discharge:</strong> Peel is extracted with process water to a dedicated filtration unit (<strong>Holdeni</strong> model) that separates peels and recirculates clean water back to the loop.</p></li><li><p><strong>Water Circuit:</strong> Closed-loop recirculation via a feed/suction pump through an integrated filtration system.</p></li></ul><h2>Control & Calibration</h2><ul><li><p><strong>Automated Control:</strong> Operating parameters (speed / dwell time / water pressure / feed rate) are set automatically via the <strong>HMI</strong>, aligned to potato type, size, and condition.</p></li><li><p><strong>Pneumatic Feed Gate:</strong> Potato dosing governed by a moving pneumatic gate linked to sensors with the upstream sections to ensure continuous, balanced flow.</p></li><li><p><strong>Downstream Transfer:</strong> Post-peeling, potatoes are conveyed to the next stage via a suitable belt.</p></li></ul><h2>Advanced Filtration System</h2><ul><li><p><strong>Peel–Water Separation:</strong> Specialized units using a physical separation principle provide complete, reliable peel isolation and return clean water to permanent-use tanks (reduced consumption and environmental protection).</p></li><li><p><strong>Cyclones for Fine Particles:</strong> For separating starch, sugars, dust, fine peels, and other unwanted particulates from the process water.</p></li><li><p><strong>Stainless-Steel Pumps:</strong> <strong>AISI 304</strong> food-grade pump set for suction and feed lines.</p></li></ul><h2>Customization</h2><ul><li><p><strong>Configurable Parameters:</strong> Tub dimensions, lining roughness, water pressure/flow, residence time, and feed rate—tunable to production capacity and site layout.</p></li></ul>